Dry Roof Testing Method

Dry roof testing is a non-destructive method of detecting leaks or breaches in flat roof membranes, particularly on non-conductive roofing systems like single-ply membranes, asphalt, bitumen, and liquid-applied systems.

Use-Cases

- Quality assurance testing after roof installation.

- Periodic maintenance checks to ensure continued integrity.

- Pre-warranty inspections.

- Post-storm inspections.

- Detection of water ingress sources in leaking roofs.

Considerations

- Requires a dry membrane for accurate testing.

- Up to 25.6mm coating thickness.

- Cannot test through overburden (e.g., gravel ballast, insulation, green roofs). Must be removed prior to testing.

1|Non-Invasive

- Testing does not damage the membrane.

- No need to flood the roof or cut into it for inspection.

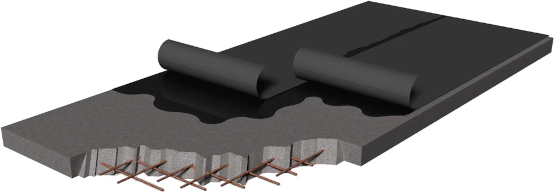

HOT-MELT ON CONCRETE DECKS

2|Highly Precise

- Detects even microscopic pinholes and breaches that are invisible to the eye.

- Immediate location pinpointing via audio/visual alerts.

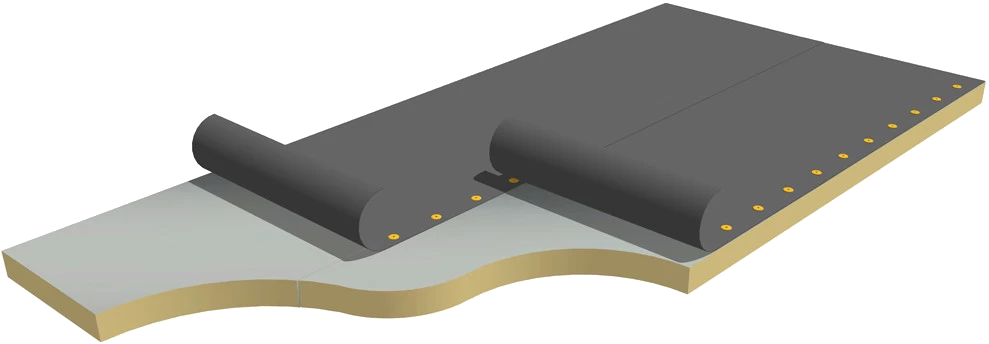

MECHANICALLY FIXED SINGLE PLY MEMBRANES ON FOIL-FACED INSULATION

3|Dry Surface Operation

- Unlike wet testing (e.g., Electronic Leak Detection or EFVM), dry roof testing can be done without water and in dry conditions — ideal for many climates or building situations.

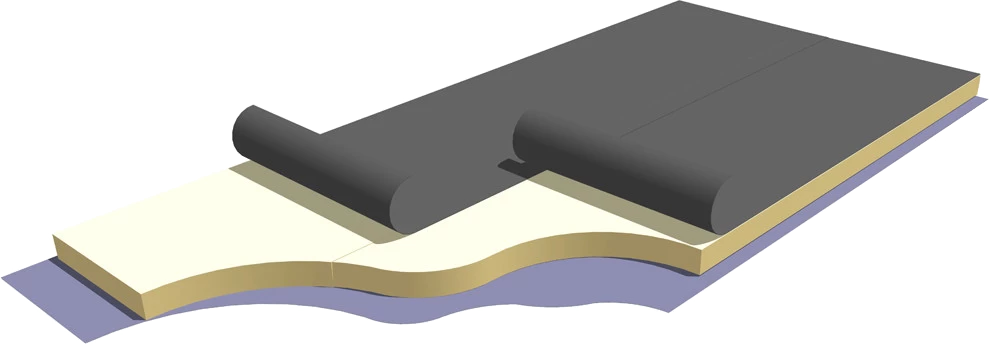

SINGLE-PLY ON TISSUE-FACED INSULATION

4|Efficient & Time-Saving

- Fast scanning of large areas.

- Reduces downtime or disruption compared to traditional testing.

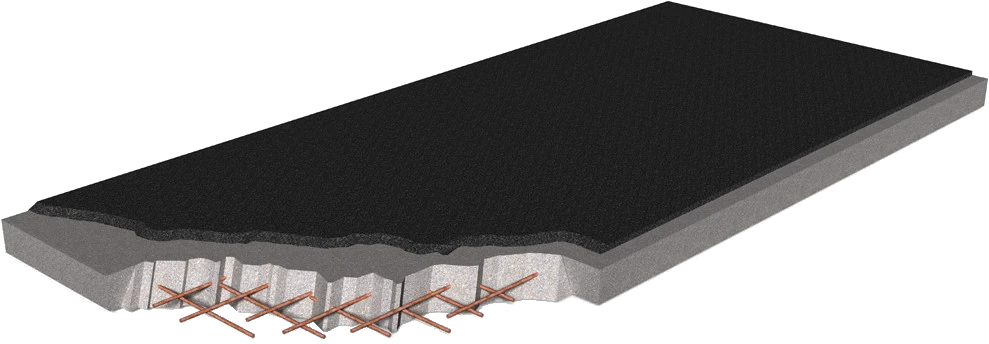

ASPHALT ON CONCRETE DECKS

5|Ideal for New and Existing Roofs

- Can be used on newly installed membranes for quality assurance.

- Also suitable for routine maintenance inspections on existing roofs.

+ MANY OTHERS

Many build-ups, including timber decks can also be tested.

Send us your detail drawings and we'll confirm.

6|Lightweight and Portable

- Minimal setup time and easy access to work areas.

- Comes with adjustable voltage to suit various membrane thicknesses.